OSE industries' analytical resources: Focus on XRF!

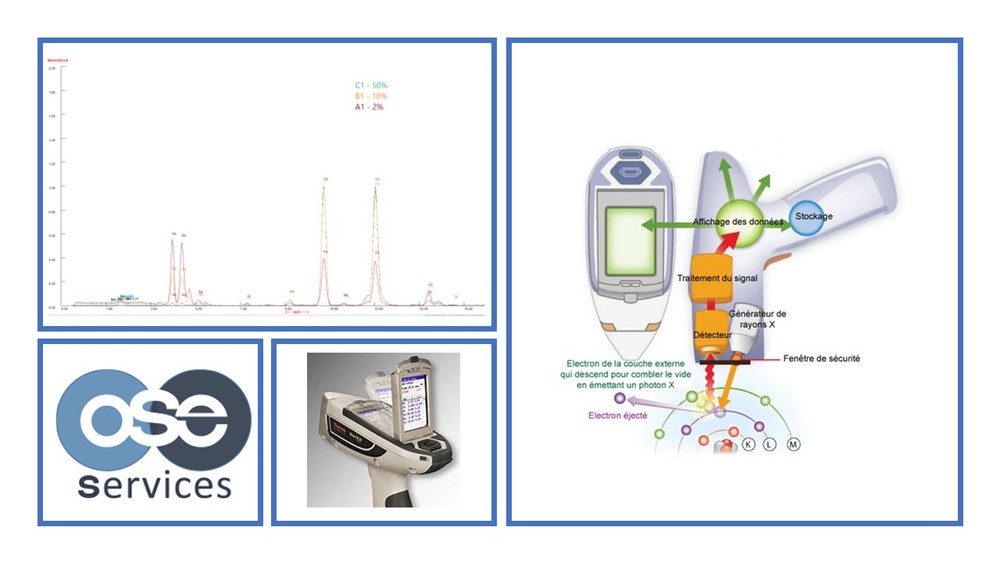

OSE SERVICES has a Niton™ XL3T GOLDD+ portable X-ray fluorescence analyser from ThermoScientific™ to offer its customers more comprehensive chemical analyses.

What is XRF?

X-ray fluorescence spectroscopy (XRF) is a non-destructive analytical technique used to determine the elemental composition of a sample. The principle of XRF spectroscopy is based on the interaction of X-rays with atomic electrons in a sample.

When a sample is exposed to high-energy X-rays, the X-rays can penetrate the surface of the material and interact with the electrons in the inner layer of the sample atoms. This interaction can cause electrons to be ejected from the inner layer of the atoms, leaving a hole in the layer.

To fill the hole, an electron from the outer layer descends to the lower energy level and emits a fluorescent X-ray that is characteristic of the element from which it originated. The energy of the X-ray emitted is specific to the element and the intensity of the X-ray is proportional to the concentration of that element in the sample.

By measuring the energies and intensities of the emitted X-rays, it is possible to determine the elemental composition of the sample. XRF spectroscopy can be used to analyse a wide range of materials, including metals, ceramics, glass and polymers. It is a widely used technique in many industries, including mining, environmental monitoring and materials science.

OSE SERVICES' analyser, the ThermoScientific™ Niton™ XL3t GOLDD+ enables reliable data acquisition in a very short time. It has multiple functions and is optimised with geometrically optimised wide area drift detector (GOLDD™) technology for improved analysis of light elements (Mg-S), very low detection thresholds and very fast measurement times.

On-site laboratory

XRF is a fast, non-invasive (non-contact), non-destructive (no sampling required) analysis technique that can qualitatively and semi-quantitatively identify several chemical elements. For OSE INDUSTRIES, the major advantage of the analyser is that it is portable. It can therefore be used on site. The OSE INDUSTRIES portable analyser can be used for many applications in situ or in the laboratory. We work throughout France, Switzerland and Europe on request.

Applications in industry

- Real-time identification of alloys and metals (stainless steels, copper alloys, nickel, aluminium, etc.);

- On-site detection of lead, chlorine, etc. ;

- Detection of heavy metals in a matrix (solid, liquid, etc.): cadmium, mercury, etc.

- On-site intervention if pollution is suspected;

- On-site analysis in the event of a production line failure;

- Analysis of plastics;

- Analysis of minerals;

- Analysis of polluted soil;

- Identification of unknown products.

Litigation and investigations

Ose Services intervenes in disputes for on-site analyses in the presence of the parties for immediate results. We operate throughout France as part of legal or amicable expert appraisals. Chemistry, Buildings, Crime Scene our expertise is based on over 15 years experience in this field.

Studies, Research and Innovation

OSE industries continues to innovate by developing in-house on-site measurement techniques adapted to new technologies and problems.

Since 2020 we have specialised in the study and verification of bio-based materials and the recovery of waste and recycled materials.

Do you have a question or a quote? Contact us