STUDY OF AN EARLY CORROSION DISPUTE: LABORATORY STUDY OF GALVANISATION

At OSE Services we intervene on site for numerous disputes and in particular for complex corrosion studies.

Here we present the case of a study linked to the presence or absence of the galvanisation layer: is it present and does it comply with the technical data sheet (thickness, size of the zinc grains, delamination of the layer, etc.)?

Galvanising is the process of coating a part with a layer of zinc to protect it from corrosion. It is one of the most commonly used treatments for steel.

OSE SERVICES supports the experts by carrying out on-site observations, sampling and analysis.

The fact that all these stages are carried out by the same company means that we can interpret the data in full context.

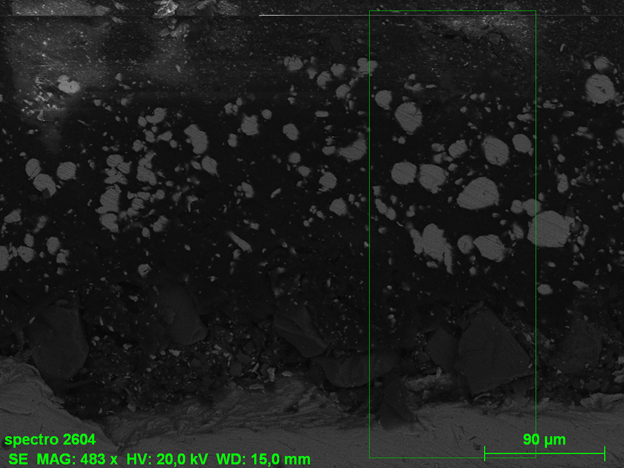

The presence of the galvanisation layer is present on this sample, which we took and prepared for SEM-EDX analysis. SEM-EDX imaging provides information on whether or not there is a galvanisation layer (zinc grains) between the paint layer (titanium) and the metal substrate (iron) and whether a preparatory layer is present. We can also check whether the thickness of this layer and the presence in cm2 of zinc grains comply with the technical data sheet.

By combining this technique with spectrometric analysis, we can distinguish between a repair layer and a deposit layer applied prior to installation.

Are you in charge of a dispute involving corrosion?